Laser marking of self-adhesive labels for fuel pumps

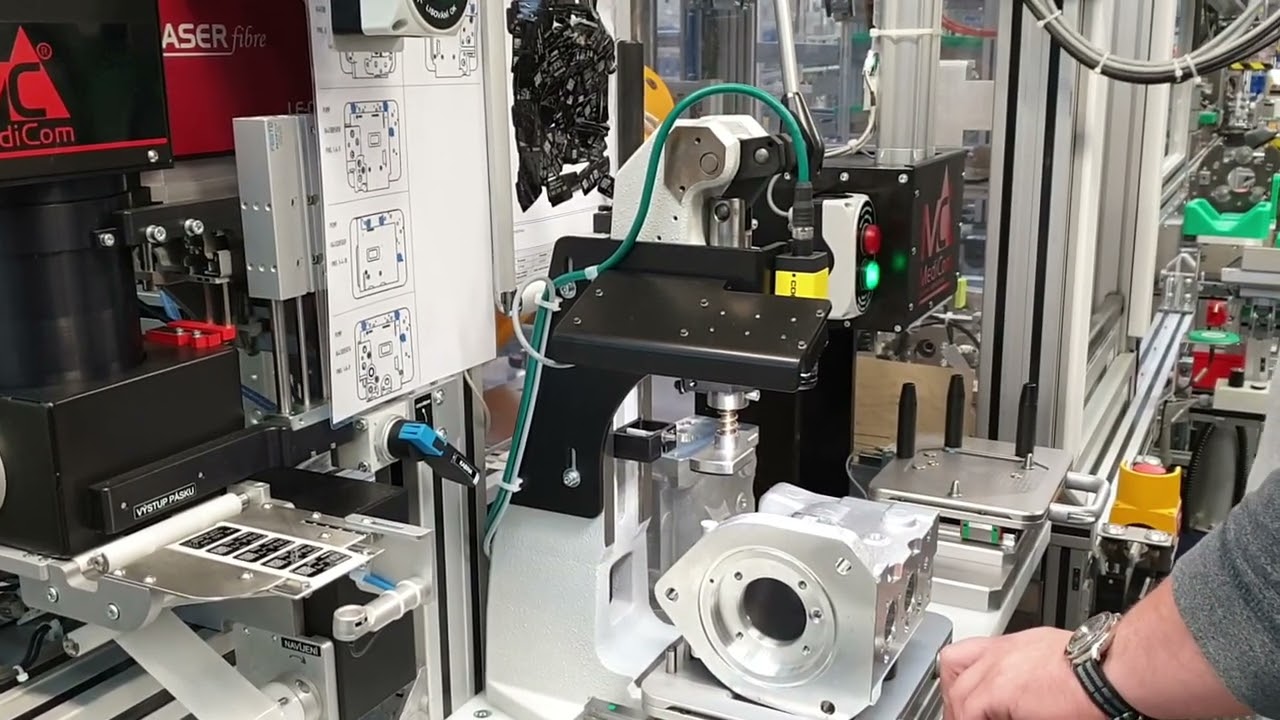

Laser station for automatic marking of self-adhesive labels with manual removal and gluing of labels on fuel pump bodiesLaser station for automatic marking of self-adhesive labels with manual removal and gluing of labels on fuel pump bodies, including hand press with defined pressure force. A control camera for reading and verifying the marked data on the label, including the DMC code, is part of the hand press station.

The station is also equipped with automatic pressing of strainers into selected types of fuel pump bodies. The automatic pressing station is equipped with monitoring and evaluation of pressing force and pressing depth.

The station also includes 2 lanes for 2 different types of labels on a tape carrier. Where for some types of pumps a label is used without a protective film and for some with a protective film. Based on the program for the given type of pump, the station automatically selects the correct track of the tape feeder and thus the correct type of label.

The station is also equipped with a secondary station for gluing the label, subsequent pressing by the second hand press and camera control in the vertical position of the pump for types where gluing of 2 duplicate labels is required. One label is then glued first in a horizontal position and then the other in a vertical position.

After each cycle, the station sends data regarding the marked label and possibly the pressing force and depth to the production server in the form of XML data.

The station is intended for 24/7 operation.

Technical parameters

Laser station for automatic marking of self-adhesive labels with manual removal and gluing of labels on fuel pump bodies, including hand press with defined pressure force. A control camera for reading and verifying the marked data on the label, including the DMC code, is part of the hand press station.

The station is intended for 24/7 operation.