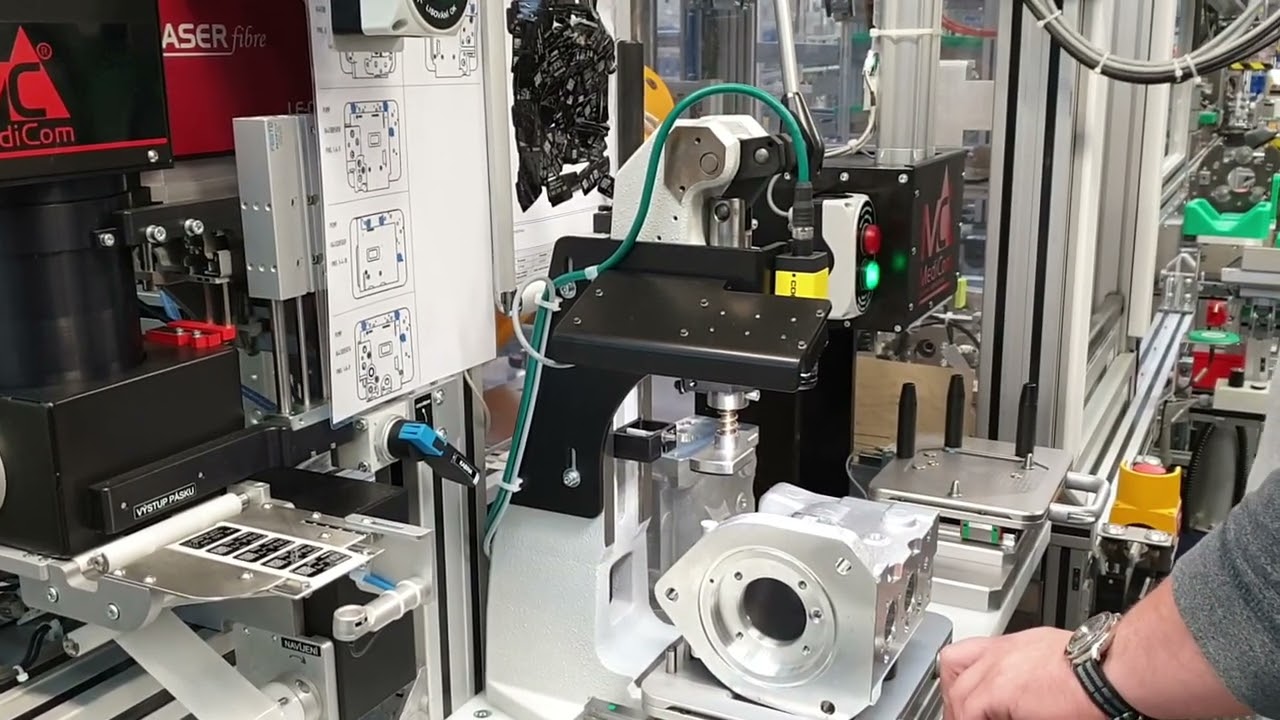

Automatic laser marking of labels

Automatic laser marking of aluminium anodized labels- The capacity of the input and output trays allows up to several hours of continuous operation

- Label output - unloading to the output tray without sorting or sorting with the resolution of individual batches

- Automatic mode - unattended fully automatic operation

- Manual mode - manual loading of parts - marking of atypical labels or other parts

- In manual mode, the laser cabin opens and closes automatically

- Operator panel with touch screen, data network connection

The station is designed for laser marking of metal labels in automatic or manual mode. Labels can be marked in piece series, optimal are series numbering 100 or more pieces. The design of the feeder allows to process aluminum labels or anodized aluminum labels, plastic or stainless-steel labels can also be marked.

The concept allows to process several different dimension types of labels without the need to readjust the machine.

Technical parameters

| Type | AMW-40 | ||||

| Laser | LASERfibre LFQ20S | ||||

Station productivity | 3500 pcs/h1) | ||||

Magazine capacity | 2400 pcs2) | ||||

Drive | pneumatic, step and DC motors | ||||

Motorized linear Z-axis - laser focus | 100 mm | ||||

Power supply | 230VAC / 50Hz | ||||

Compressed air | 6 bar | ||||

Input | 800 W | ||||

Station dimensions | 1800 (W) x 1100 (D) x 1900 (H) mm | ||||

Station weight | 650 kg | ||||

Cooling | Air surrounding temperature 15°- 35°C | ||||

Application software | WMark | ||||

Operating system | Windows 10 | ||||

Certificates | Laser class I, CE mark | ||||

1) according to the label marking time, which depends on the complexity of the marking layout

2)for label thickness 0.5mm