Laser marking of self-adhesive labels

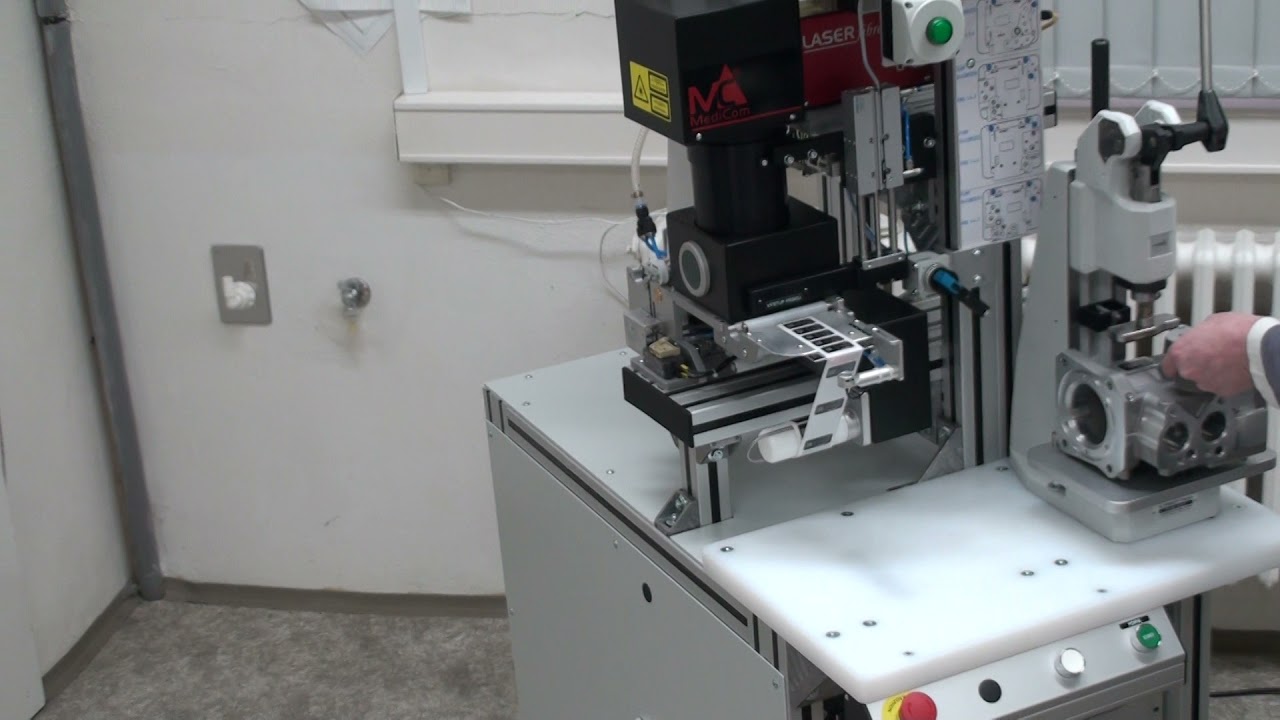

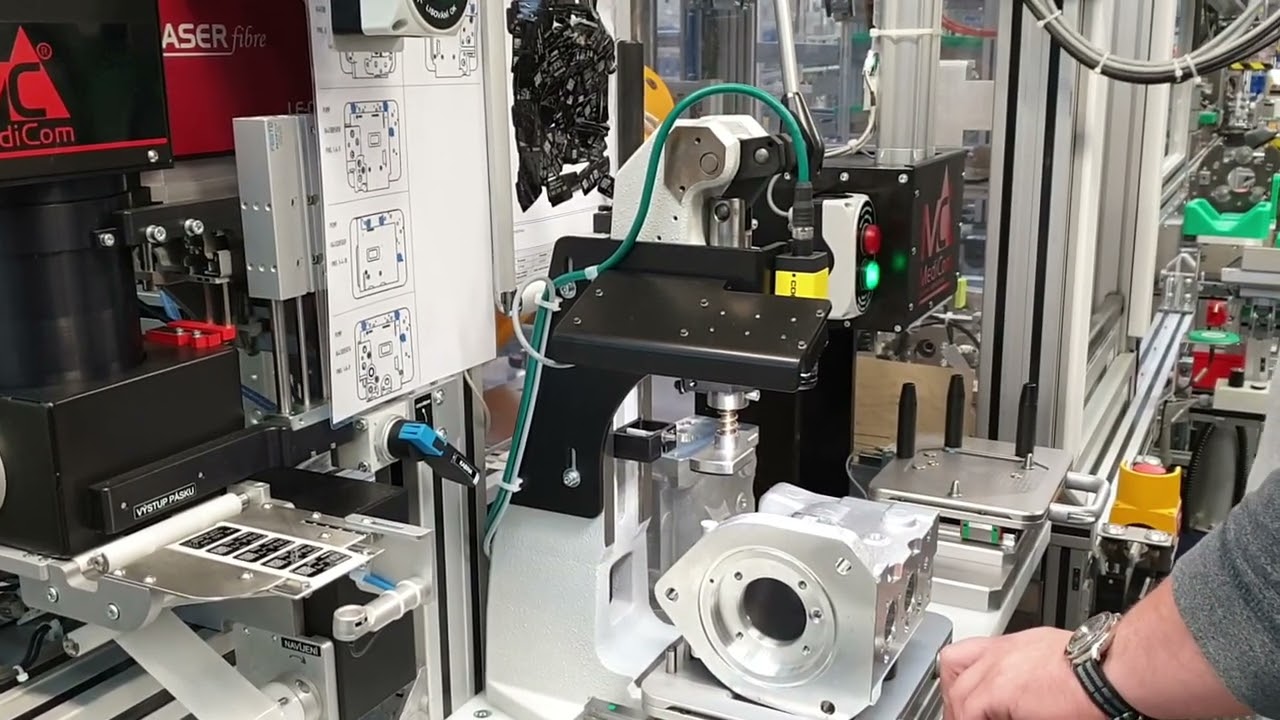

Laser automatic marking workstation- Automatic mode of unwinding and rewinding from roll to roll

- Manual mode with single pickup of individual labels to the operator

- Fully automatic unwinding and rewinding

- Possibility of adding a cutter

- Check and verification of barcodes or data matrix codes with a reader

- Label self-destruction in case of unreadable code

The station is equipped with an automatic self-adhesive label feeder. The labels are affixed to the carrier and pass through the feeder, where they are precisely positioned and marked. At the output, they can be rewound on a roll or, in a variant version of the feeder, they can be removed one piece at a time. The label carrier guide can be interchangeable (= readjustment speed) or adjustable (= versatility). Either the edge of the label or the synchronization mark on the carrier can be detected.

Technical parameters

| Type | AMW-02 | ||||

| Laser | LASERfibre LFQ20S | ||||

| Station productivity | 4000 pcs/h1) | ||||

Magazine capacity | 1 roll2) | ||||

| Drive | pneumatic, step and DC motors | ||||

| Z axis - laser focus | fixed | ||||

Power supply | 230VAC / 50Hz | ||||

Compressed air | 6 bar | ||||

Input | 800 W | ||||

Station dimensions | 800 (W) x 800 (D) x 1600 (H) mm | ||||

Station weight | 120 kg | ||||

Cooling | Air surrounding temperature 15°- 35°C | ||||

Application software | WMark | ||||

Operating system | Windows 10 | ||||

Certificates | Laser class I, CE mark | ||||

1) according to the label marking time, which depends on the complexity of the marking layout

2) typical capacity of 1 roll = 5000 or 10000 labels