Laser marking of bearings

Automatic laser marking station for marking of bearingsThe station is designed for laser marking of bearings or bearing rings in a smooth design, possibly with one or more collars.

The station can operate in three modes of operation:

- Manual - the parts are manually loaded into the marking cabin and removed manually after marking

- Semi-automatic - parts are manually loaded into the marking cabin and unloaded automatically on the output conveyor

- Automatic - parts are picked up automatically from the input tray and automatically unloaded into the output container after marking

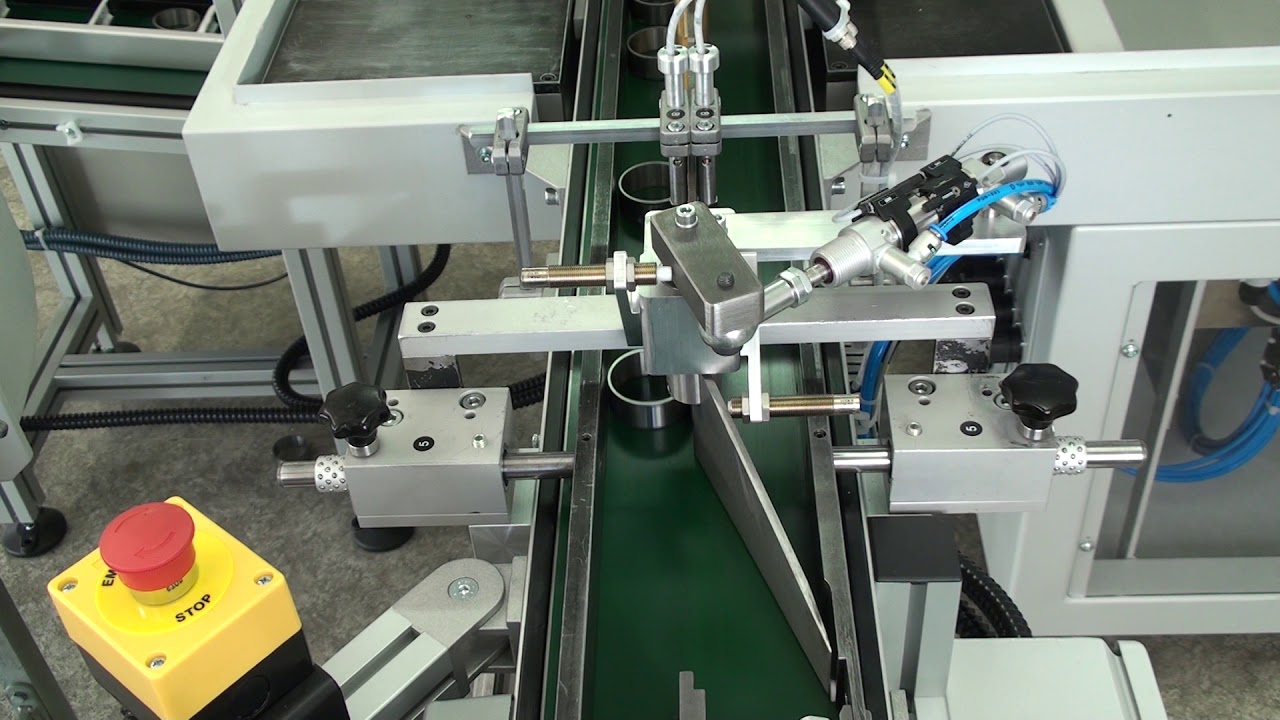

The automatic part of the station consists of an input rotary tray for parts, a laser-fitted parts feeder and an output conveyor with a marked parts tray. The rotary tray has a capacity of several hundred pieces and allows continuous operation for several hours. The feeder automatically picks up individual pieces, then precisely fixes the marked part and unloads the marked part on the export conveyor.

The output export conveyor exports and stores parts in a container.

Other accessories:

- Motorized door for access to the marking cabin in manual and semi-automatic mode

- Controlled Z-axis (laser focusing)

- Additional rotary axis for circumferential marking of cylindrical parts (in manual mode)

- Possibility of adding a demagnetization unit

Technical parameters

| Type | AMW-84 | ||||

| Laser | LASERdiode LD50-S | ||||

Station productivity | 2400 pcs/h1) | ||||

Magazine capacity | 2000 pcs2) | ||||

Drive | pneumatic, step motors | ||||

Motorized Z-axis for laser focusing | 200 mm | ||||

Power supply | 230VAC / 50Hz | ||||

Compressed air | 6 bar | ||||

Input | 1800 W | ||||

Station dimensions | 2060 (W) x 3200 (D) x 1600 (H) mm | ||||

Station weight | 450 kg | ||||

Cooling | water - water-air exchanger surrounding temperature: 15° ÷ 35°C | ||||

Application software | WMark | ||||

Operating system | Windows 10 | ||||

Certificates | Laser class I, CE mark | ||||

1) according to the part marking time, which depends on the complexity of the marking layout

2)according to the size of the parts